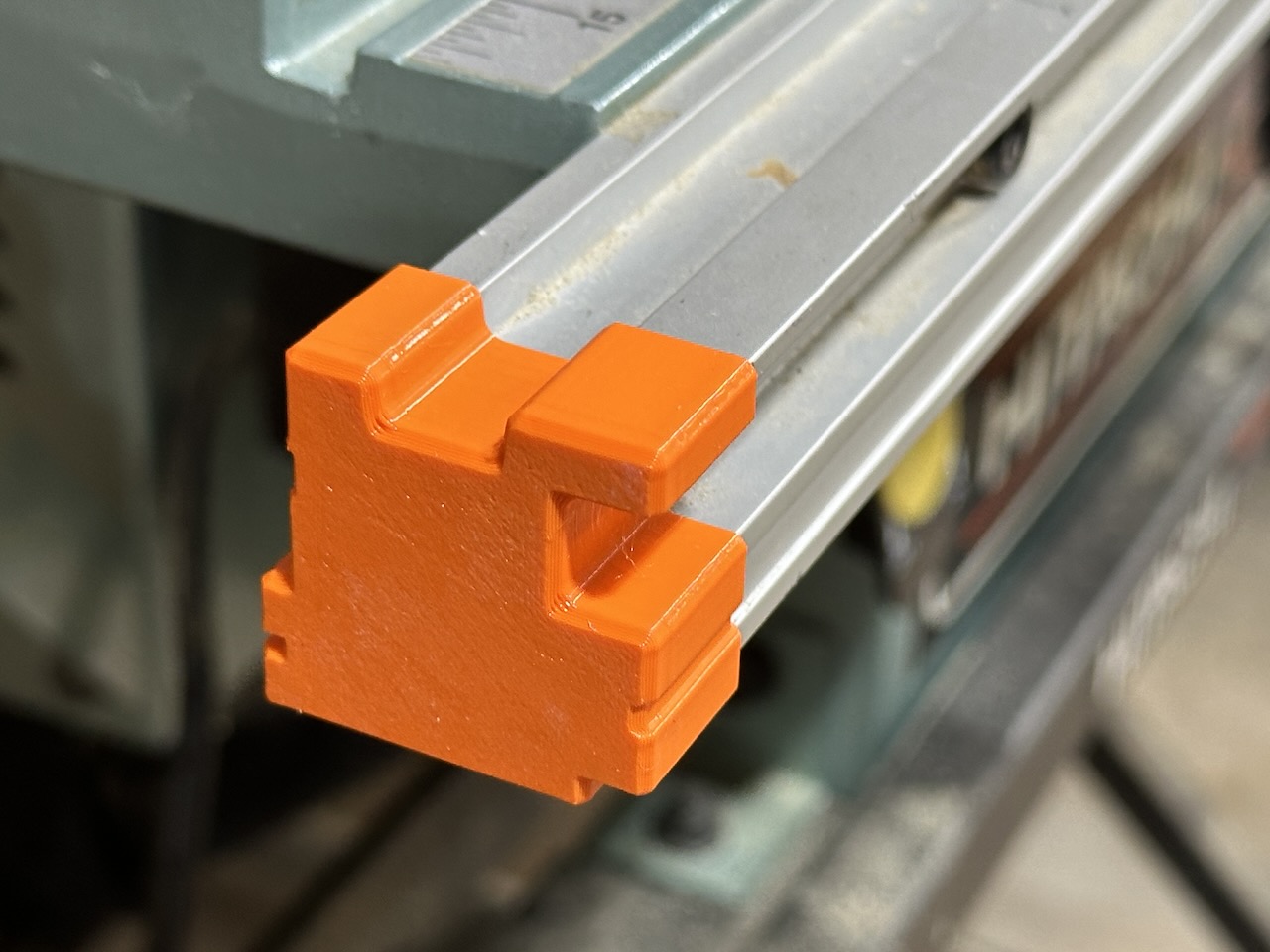

Making 3D-printed end caps for sharp aluminum extrusions

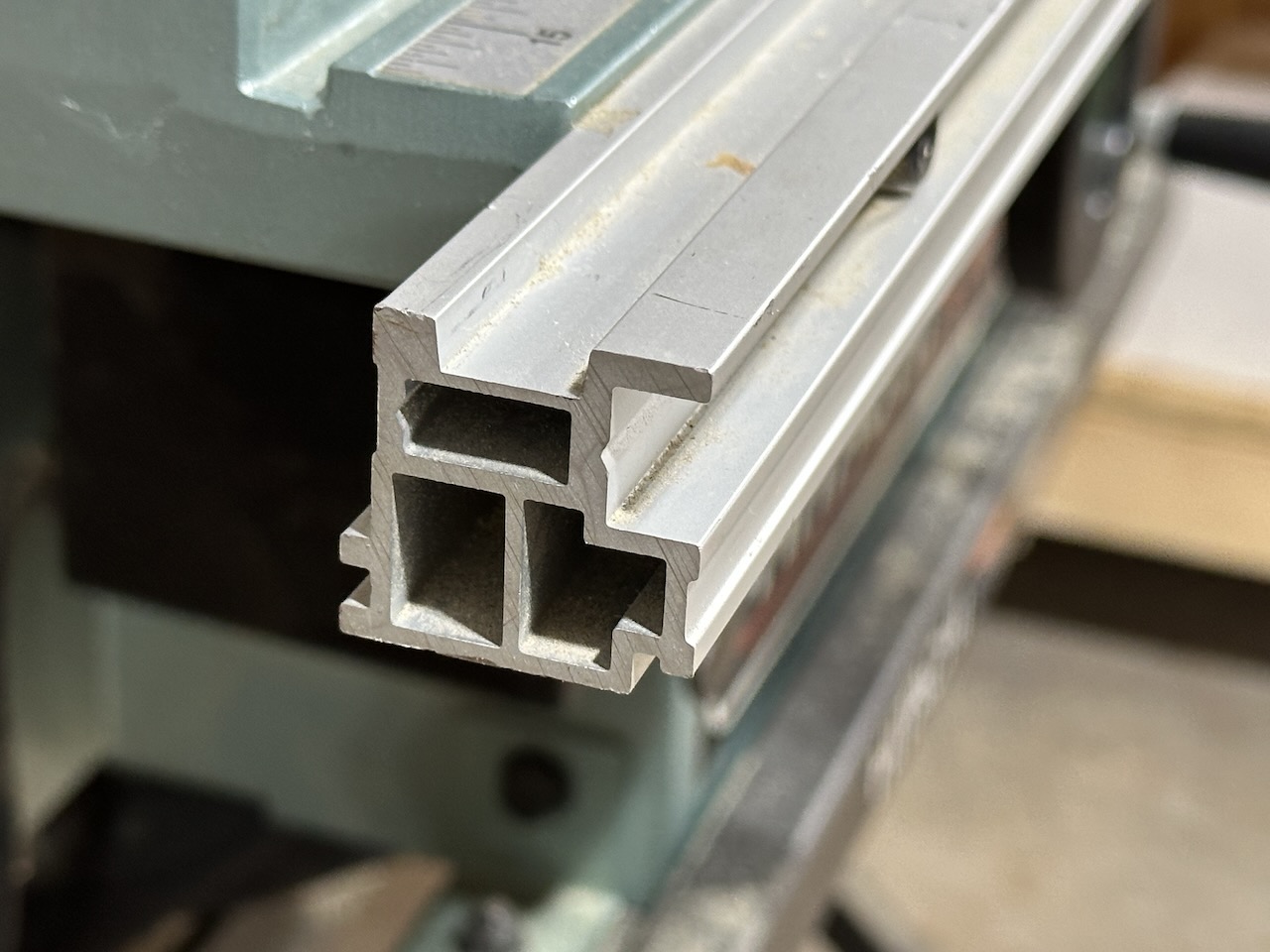

My table saw — a portable Hitachi C10RA2 I bought from a friend — features two aluminum extrusions along the table top. These extrusions stick out a bit on each side of the saw, and they have sharp corners, and they hurt when you bump into them:

I chose to take a decidedly extra approach to solving this problem.

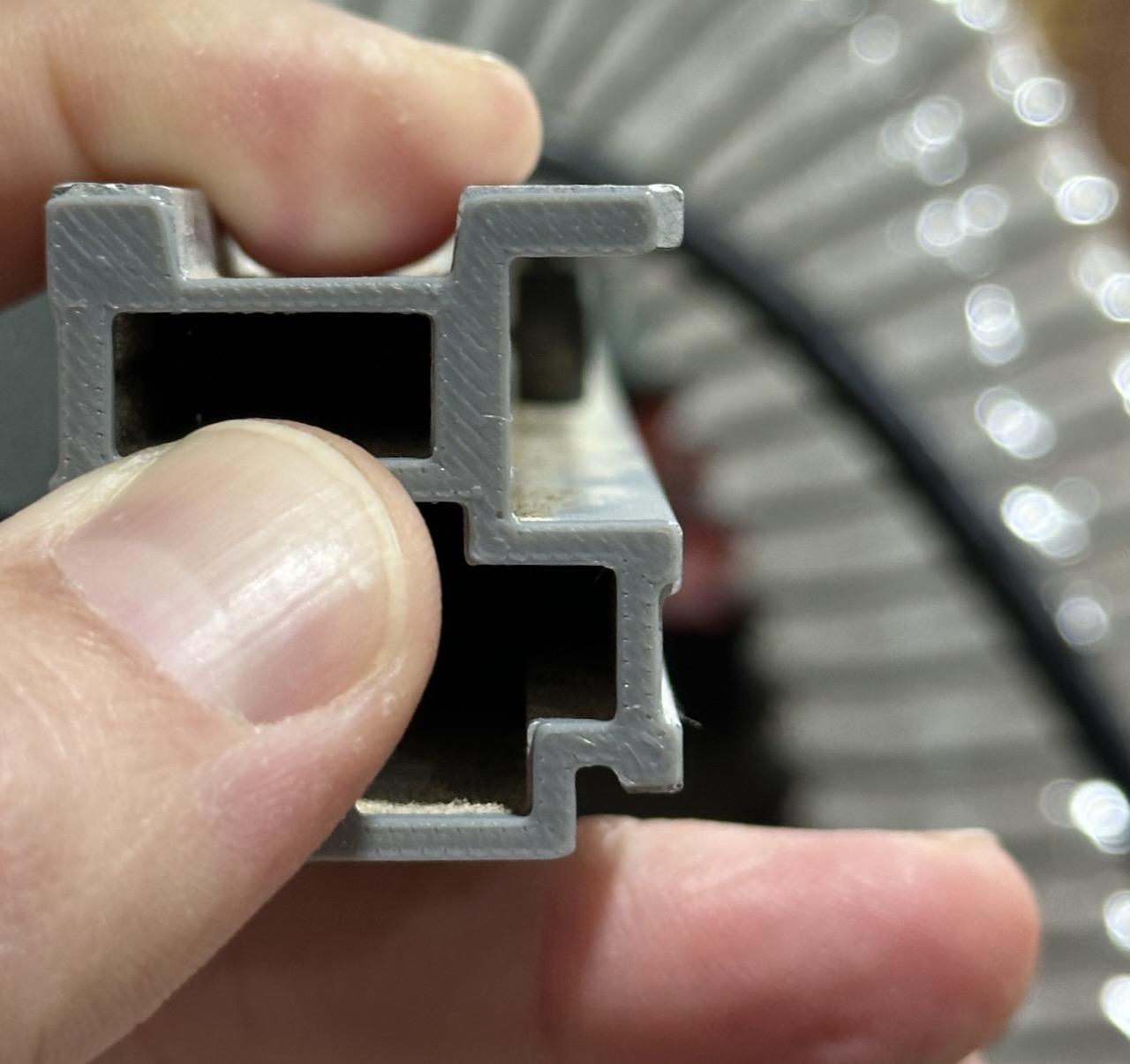

First, I modeled the extrusions’ profile in Autodesk Fusion. I took measurements and made a rough first version, then 3D-printed the profile in a few layers of PLA. This allowed me to compare my work-in-progress to the actual extrusion, so I knew what needed to be re-measured and adjusted:

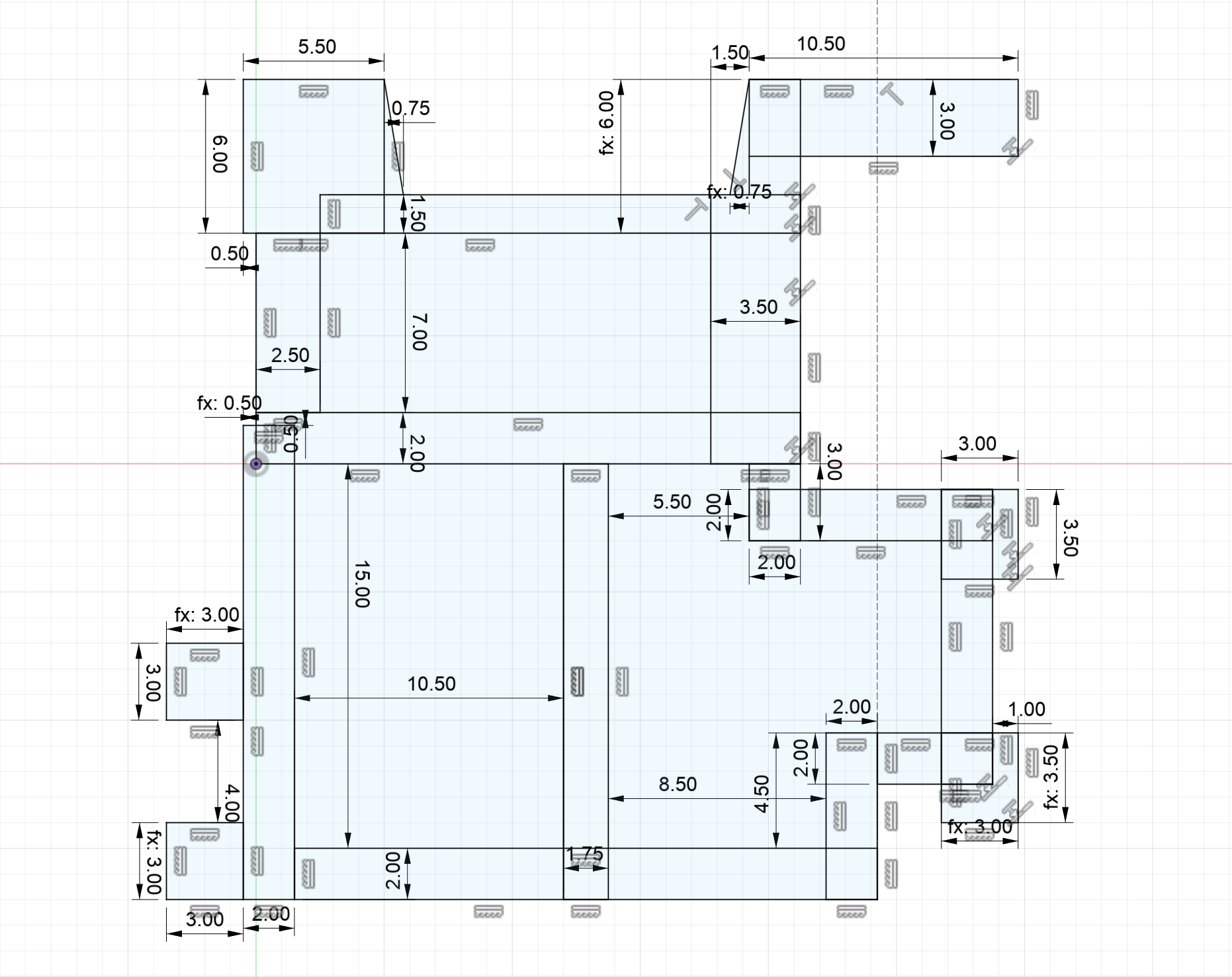

It took me 6 or 7 iterations to get my CAD version of the extrusion’s profile perfect. Happily, printing those iterations made for a pretty quick feedback loop. The resulting sketch is complex and probably doesn’t follow some CAD best practices, but I’m not a professional, and anyway it worked!

Once that was done, I modeled two end caps (one a reflection of the other). They use walls offset 0.1mm from the actual extrusion profile. This value seems to provide a good fit; they’re definitely not going to fall off, but I didn’t need to use a hammer to install them either.

(This embedded 3D viewer is very much a work in progress; please forgive its flakiness!)

I printed the caps in orange Overture-brand high-speed 95A TPU. The result, I think, looks almost professional: